Factory design and construction projects

Factory design and construction projects As a strong and powerful factory manufacturer, the design and construction of factories with appropriate space and cost, necessary facilities and according to the needs of the employer, is what distinguishes us in the design and construction of factories. We design and build the factory in the best possible way..

One of the fields of activity of Ista Banaye Rasakh Company is the design and construction of knowledge-based factories and manufacturing companies, which is a specialized and engineering process. From consultation and design operations to construction operations and compliance with construction standards and regulations, especially in industrial towns or special industrial areas, are processes that must be carried out carefully and with high quality.

Table of Contents:

- How is the construction of the factory done?

- Factory construction clip

- Factory construction steps

- Description of factory design services

- Description of factory contract management services

- Factory design and setup projects

How is the construction of the factory done?

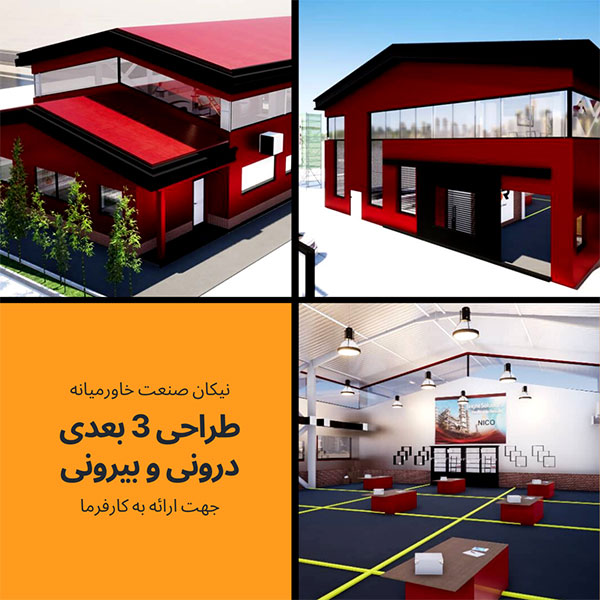

important points should be considered before building the factory, which we will discuss in this article. To build a factory, there are steps, each of these steps must be done in a principled way. But before that, I invite you to watch part of the design and construction stages of Nikan Sanate Khavarmianeh factory .

Factory design and construction clip

Factory construction steps

Here, with an example of the Nikan Sanat Khavarmianeh factory project, we explain these steps to you:

1. Zero phase studies and consultations before designing the factory

Architecture zero phase design services include location maps and alignment of the site plan.

2. 3D modeling for factory facade design

In the second step, after receiving the client’s opinions and preferences and in accordance with the factory construction standards, the architectural experts of Ista Benaye Rasakh Company, which consists of an experienced and brilliant team, starts the architectural design process of the zero phase and then performs the 3D modeling of the factory facade. This design is reviewed many times and finally the design approved by both parties goes to the next stages for the implementation process.

3. Excavation and implementation of earthworks

After confirming the design of the factory, the company’s engineers go to the project site and carry out excavation operations according to the architect’s drawings.

4. Concrete pouring and implementation of foundation operations

After the excavation operation is completed, it is time for the foundation implementation phase, in which concrete pouring of the factory’s foundation is done to maintain its strength.

5. steel frame installation

Now that the foundation operation is done, it is time to install the steel frame to form the steel structure. This skeleton is installed in its places according to the designer’s drawings.

6. Implementation of steel deck roof

Steel deck roofs are very popular these days due to their more reasonable cost and faster execution speed. Our company also uses steel deck roofs to increase the quality of construction and reduce its costs. After the metal frame is installed, the operation of the steel deck roof is performed and then the corresponding concreting is done.

7. Brickwork of the factory and area

After preparing the skeleton and roofs of the factory, it’s time to put up walls and complete the structure. At this stage, the workers do the brickwork of the factory walls and its area.

8. Implementation and execution of the factory view

Now that the building of the factory is completed, it is time to complete the appearance of the factory. At this stage, the view of the factory or knowledge-based company is implemented according to the opinion and choice of the employer. In the example of Nikan Sanat factory, we used sandwich panel sheets to complete the facade of the factory.

9. Complementary operation

So far, we are almost at the end of the factory construction. There are only minor items about internal operations and such, after which the project is over.

If you need a suitable and standard space to promote your knowledge-based business and production, you should consider setting up a factory or an industrial complex. Having a factory with suitable space and necessary facilities is the desire of every producer. With our expert team, we provide all your needs in the construction and establishment of the factory.

Contact us for free consultation regarding studies, design, construction and operation of your factory.

Necessary points in factory design

There are factors that must be considered in the design of the factory. So, if you want to design and build a new factory, consider these things.

1. The nature of the production process

Buildings required to house continuous or intermittent manufacturing processes are very different in design. It is rare that a building is suitable for both types of knowledge-based production. The design and construction of the factory is different according to the type of product and the equipment used.

Knowledge-based factories that produce rubber, clothing, machinery, glass bottles, presses or steel plates have designs that differ in terms of loading, ceiling height, enclosure size, ventilation and humidity, etc.

2. flexibility

Suppose a factory owner is interested in abandoning his original product and deciding to produce another knowledge-based product that is likely to be more profitable. He cannot build another factory and is thinking of using the same old factory building to build a new product. This is not a strange thing.

Many of the old cotton and sugar mills are now used for light engineering work. Here, a question arises as to whether the old factory building has the necessary flexibility to make the new product?

Therefore, flexibility in plant design prevents it from becoming obsolete and gives it the same operational efficiency (the old plant) even if there is a change in product, process or technology.

Flexibility can be increased by:

- Creating a large floor without obstructing columns that make processes and layouts easily changeable.

- Maintaining sufficient roof truss strength and ceiling height in order to install newer equipment to use materials and control the temperature inside the factory

- Not creating permanent obstructions such as walls and partitions on the production floor

- Providing individual motor drives for machines

- Providing the power grid at different voltage levels overhead, so that the power supply can be used near the equipment.

- Create resistant floors to accommodate heavier equipment

- The installation and operation of the device should be such that the machines can be easily moved if the layout needs to be changed.

3. Expandability or expansion in the future

Maintaining supplies for future expansion has become imperative due to the massive expansion of the industry in recent years. During the construction of the new factory, due attention is paid to future expansions. But before that, a factory site large enough for current needs and future expansion needs must be purchased.

During the design of the factory, you should also think carefully about the future, whether the factory will expand in terms of length and width or if new floors will be added to it. If it is decided to expand in length and width, false and non-load-bearing end walls are made to facilitate flexibility. If more floors are to be added, proper footings, supports, etc. should be provided in the main structure to support the weight of the added floor.

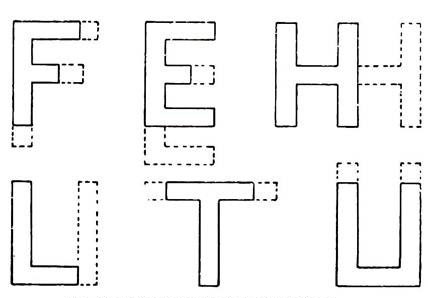

Where operations are housed in separate buildings certain forms of layout have become popular due to ease of expansion and are in the form of the letters F, E, H, L, U, T. The original building is in solid lines and the extensions are shown as dotted lines.

4. Service facilities

Service facilities such as fire extinguishing equipment, sewage treatment systems, emergency and standby power equipment, compressed air equipment, heating equipment, lighting, air conditioning, etc. should be kept separately and properly.

5. Employee facilities

The presence of good facilities is a motivation for the employees of an organization and increases their morale. In the case of washrooms and toilets, clinics, dining halls, recreation rooms, parking lots, etc., knowledge base factory and company must have sufficient conditions.

6. the light

One of the most important environmental factors is light, which increases productivity, reduces accidents and employee satisfaction. Among the advantages of good light in the design and construction of the factory are:

- Increasing production and reducing costs

- Reducing accidents and incidents

- Better vision and less pressure on the eyes

- Less corruption

- The cleanliness of the factory can be better maintained

- Easier and better monitoring of materials in the process and finished products

- Improving morale among employees

Good light properties

- The light must be of sufficient intensity for the specific operation being performed.

- The light should be equally bright in most places

- There should be sufficient but not sharp contrast between each part of an object and the surrounding background.

- Light should not create shadows.

- Beneficial light should not be used.

The nature of light

- Natural light is the best light for work, but it varies according to the time of day and year and weather conditions (especially cloudy). It also varies with the size and position of the windows, and besides, it is not possible to adjust the intensity of natural light. This necessitates the use of artificial light.

- Artificial light is designed to complement natural light. Artificial light, during the day, only provides light to areas that do not have enough light to work.

Artificial light sources

- Incandescent lamp

- Fluorescent lamp

- Mercury vapor lamp

Incandescent bulbs are inexpensive, easy to install, and come in a variety of wattages. But these lamps have low efficiency and are suitable for local use. In fact, they replace fluorescent lamps.

Fluorescent lamps have high efficiency and are commonly used in factories. These lamps have low consumption and long life. Their brightness is low and they are available in different colors.

Mercury vapor lamps have more light and longer life and are easy to maintain. Its blue-green light gives an unnatural appearance. Mercury vapor lamps are used in large areas for general industrial lighting.

7. heating system

In the design and construction of factories and companies, the knowledge base of the heating system is important for the following reasons:

- Processing: Heat is needed for melting metals, alloys and forging

- Heating in the workplace: A heating system is needed to improve the performance of employees in the winter season. The ideal temperature in the workplace should be 15 to 18 degrees Celsius.

- Cooking factory meals

Heating sources for:

Processes and operations: electric or oil or coal furnaces, steam boilers

Workplace heating: electric heater, charcoal stove

Cooking: gas or electric oven

The fuel is usually burned centrally and the heat is transferred to different work places with the help of pipes containing hot water, steam or hot air. Heating systems can be controlled automatically.

8. Ventilation

Ventilation basically replaces stale factory air with fresh air. If the stale air is not removed, it will smell bad and the concentration of carbon dioxide, humidity and temperature will increase. Improper ventilation leads to discomfort and fatigue. Modern factories provide air conditioning for their employees with hourly air changes.

Ventilation methods

- Natural ventilation through doors and windows

- Mechanical ventilation using exhaust fans to extract stale air from the factory building

9. temperature

Air conditioning is the control of air temperature, humidity, cleanliness and air distribution. Temperature control includes heating the air in winter and cooling it in summer. Plant heat may be generated through hot water or steam or a heat source

10. other things

1. Factory view

A good look can be achieved by using attractive colors, glass and metal parts. Architectural style and building materials are responsible for the good appearance of a factory.

2. A strong, durable, economical and safe structure

Use metal structures for roofing and strength. Use prefabricated doors and windows. Precast concrete construction may also be beneficial.

3. Security measures

This work includes preparing barbed wires, placing broken glass pieces on border walls, keeping explosive and flammable materials outside the factory building in separate compartments, etc.

4. Sound control

Minimize unwanted sounds to reduce workers’ mental fatigue (do not lead to) accidents and industrial deafness.

Ista Banaye Rasekh Construction Engineering Company provides consulting, design, management and implementation services of various industrial projects inside and outside industrial towns all over the country. Designing and setting up a knowledge-based factory and company is one of our specialized fields. Some projects include:

- Industrial complexes

- Production complexes

- Agricultural and industrial complexes

- Light livestock and cattle breeding complexed

Also, please contact us for free consultation regarding renovation, improvement (overhaul), retrofitting and development of your complex or factory.

Ista Banaye Rasekh Company is the leader in providing technical engineering services in the field of industrial projects. This company has a complete engineering team in the field of engineering and civil engineering

Description of factory design services

- Studies and zero phase

- Facade design and interior design

- architecture

- Phase one (plan and cut map)

- Phase two (map of executive details)

- Structure

- Structure map

- 3D computational model + computational notebook

- 3D shopping model

- Mechanical

- • First phase – >General maps

- • Second phase -> specialized maps with implementation details

- Electrical facilities

- • First phase – >General maps

- • Second phase -> specialized maps with implementation details

Zero phase architecture

The description of architectural phase zero design services, including location maps and alignment of the site plan, is as follows:

- Placement of user spaces such as entrances and exits, service spaces, side buildings and other required buildings in the site plan (and in industrial factories items such as docks, input and output load scales, central engine houses, production halls, etc.) as well as site alignment maps and User tables in the form of staining

- Field visits and investigation of existing land conditions and preparation of detailed billet maps and alignment of existing structures

- Examining the condition of user spaces based on the needs of employers

- Review of land topography studies, including the optimal volumes of excavation and embankment, which are inferred from the results of the elevation levels of the land.

- Investigating geotechnical studies including the type and soil resistance parameters, permeability and slope angle of the trench, etc. based on the output results of the soil mechanics laboratory.

- Examining the types and causes of accesses and the connection between the site and the main and secondary roads, reducing the access and circulation spaces of heavy machinery and merging with the firefighting day standards in order to use the maximum allowed area of the infrastructure.

- • Examining urban or industrial construction criteria and including these criteria in zero phase design

- Studying the special characteristics of the site, such as electricity pylons, sound, pleasant and unpleasant smells, noise and air pollution, favorable and unfavorable views, etc.

- Examining points such as the amount of snowfall, humidity and local temperature at different times of the month and year, the path of the sun and its vertical angle at various times of the year, favorable and unfavorable winds based on the statistics of official organizations

- Providing leveling maps of user spaces, dock area and machinery passageways in such a way that, in addition to providing safe and standard guidance of surface water, the most optimal volumes of earthworks are obtained.

Phase one architecture

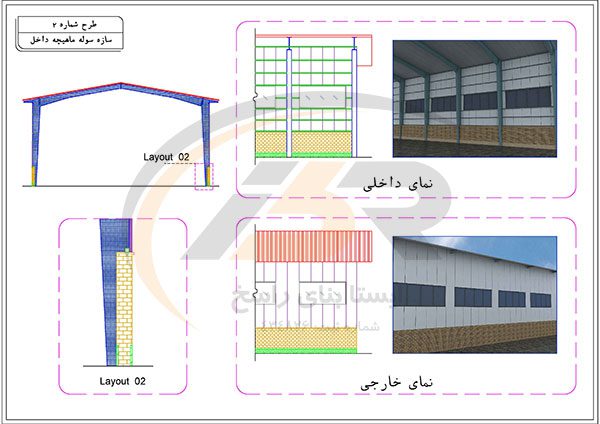

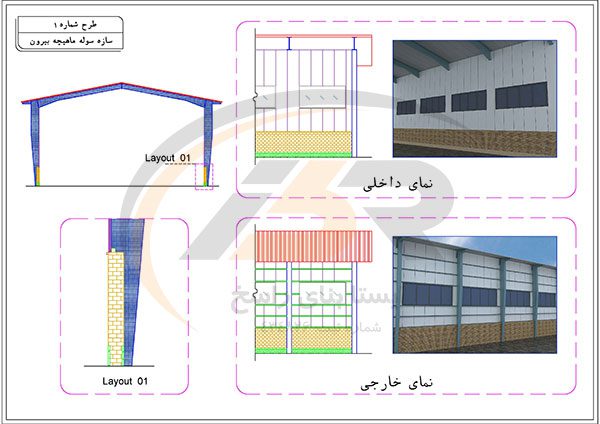

Based on the output of the approved phase zero maps, phase one architecture maps are designed. The description of the architecture design phase one service, including the interior plan maps and cutting sections of the sheds and its external area, is as follows:

- Accurate axis maps of sheds based on the output of architectural zero-phase spotting maps

- The plan of the interior spaces of the sheds is designed and presented by specialized architectural teams based on the needs and requirements of the production lines, which are presented in joint meetings with the experts introduced by the client.

- Providing the longitudinal and transverse sections of the sheds based on the required height of the production lines, the permissible slope of the roof and the maximum permissible height of the structure.

- Presentation of four-sided facade plans, arrangement of entrance doors and windows providing light

- Providing material tables according to the type of use of indoor and outdoor spaces

Phase two architecture

Based on the output of the four maps (architecture, structure, electrical and mechanical facilities) and the matching of these maps with the phase two architecture maps (detailed construction maps) with the following service description will be provided:

- Detailed measurement plans for the location of user spaces, floor architecture, roof slope

- Enlargement of user spaces such as production halls, warehouses, raw material tanks, office buildings, service and health services, etc.

- Placement of electrical and mechanical facilities

- Accurate measurement along with executive details of views

- Executive details of longitudinal and transverse sections, wall posts, floor covering, stairs, etc

- Designing a special or conceptual view and its 3D renderings at the request of the respected employer

Description of factory construction contract management services

Management of various stages of work, supervision of the good implementation of the construction operations of the factory development plan and communication with regulatory and legal approving authorities, planning the progress of implementation and providing relevant reports to the respected employer are part of the description of contract management services. These services briefly include the following:

- It is the responsibility of the contract manager to comply with the cost-effectiveness of the respected employer in all stages of building construction.

- Preparing and coordinating the purchase of all materials needed for the project with the recognition and cost of the respected employer and obtaining approval from them. Presenting the project implementation costs according to the drawings and technical specifications and different implementation methods in a comparative manner to the esteemed employer so that he can make a decision regarding the choice of material and the type of implementation method.

- Use of suitable materials according to the technical specifications presented in the map

- Providing scheduling and budgeting based on general activities and sub-activities of the project in the form of Microsoft Project (MSP) and providing monthly reports of project progress and the actual budget of the project based on the activities carried out and the delays that have occurred and providing a solution to compensate for the delay for the efficiency and effectiveness of the project. is the contract manager.

- All contracts concluded with contractors are prepared by the contract manager and placed at the disposal of the respected employer for review and conclusion of the contract.

- Submitting the certified status report of contractors to the respected employer and confirming the activities performed, observing the necessary aspects in payments to contractors and sub-contractors.

- Provision of technical agents and sub-contractors required for the implementation of the executive operations of the contract management period and introduction to the esteemed employer and obtaining approval from him. Establishment and continuous supervision of engineering technical forces of the contract manager

- Necessary follow-up for supervisors to visit the various stages of the project and obtain necessary quality approvals for each stage of the work and get the work approved by the competent authorities.

- Obtaining inquiries for the purchase of required items and materials from at least three vendors or contractors and presenting it to the respected employer for decision.

- Observance of private conditions and specifications contained in the building permit and approved plans in the execution of the work

- The contract manager’s fee is paid to the contract manager based on a percentage of the construction costs. This manager is guaranteed to save the overall costs of the construction of the factory by applying the correct implementation methods and complying with the time and financial aspects of the project, so that in addition to the economic efficiency of the contract management fee, it also reduces the total costs.

Factory design and setup projects

- Shokat Razan Hamadan Company

- Development and retrofitting plan for Ahangari Novin

- Qom hydropower plant construction project

- Sharifabad Agriculture and Industry Design and Supervision Project

- Study plan and design of buffalo breeding in Shush city

- Nikan Sanat Khavarmianeh project

- Study plan and design of Maragheh Cattle Project

- Project of Faraz Pardazesh Arka Company (Arkel)

- The project of Parsa Fartak Dade Vira Company

The year 1401: the year of production, knowledge-based and job-creating – we stand by the respectable producers..

Ista Bana Rasakh Company as the strongest factory building team In Iran, like other previous industrial projects, it proudly announces its readiness to advise you, the industrialist. We are proud to be your technical and engineering support in the field of development and construction of your factory in the year of production, support and removal of obstacles..

Contact us to start cooperation and free consultation in the field of development, construction and renovation of your factory.

How much does it cost to build a factory?

The cost of building and setting up a factory varies depending on the type of projects and price fluctuations. Therefore, the exact price cannot be announced. But on average, the cost of setting up a factory is 4 million tomans per square meter.

What does a factory need?

Attractive design and appearance, strong and stable building, the ability to develop and expand the space in the future, service facilities, heating-cooling systems, ventilation systems, proper lighting, sound control and insulation, security measures

What factories can Ista Bana Rasekh Company set up?

Ista Banaye Rasekh company has the ability to design and build various industrial and production factories, including (mineral water, papermaking, cement, steel, toys, asphalt, auto parts, clothing, food, flour, oxygen, dairy, ceramic tiles, waste recycling, detergents, animal feed, pharmaceuticals, alcohol production, recycling, etc.).

Do we do construction and factory construction in foreign countries?

Yes – Ista Banaye Rasekh Company designs and builds factories in other countries, especially friendly countries (Iraq, Syria, Oman and Lebanon) and neighboring countries.

بدون دیدگاه